Adhesive Cement Laboratory

The Adhesive Cement Laboratory is dedicated to ensuring the quality and reliability of adhesive cement materials. Utilizing specialized instruments and rigorous testing procedures, the lab demonstrates a commitment to maintaining the highest industry standards. Clients can trust in the accuracy and precision of the results, supported by a steadfast dedication to excellence in every aspect of the work.

Instruments and Processes:

- Oven: The oven is used to prepare samples by applying controlled heating. This process is essential for testing the properties and behavior of adhesive cement under varying temperature conditions. Samples are placed in the oven, where controlled heating simulates real-world scenarios, allowing an assessment of how adhesive cement performs under different temperatures.

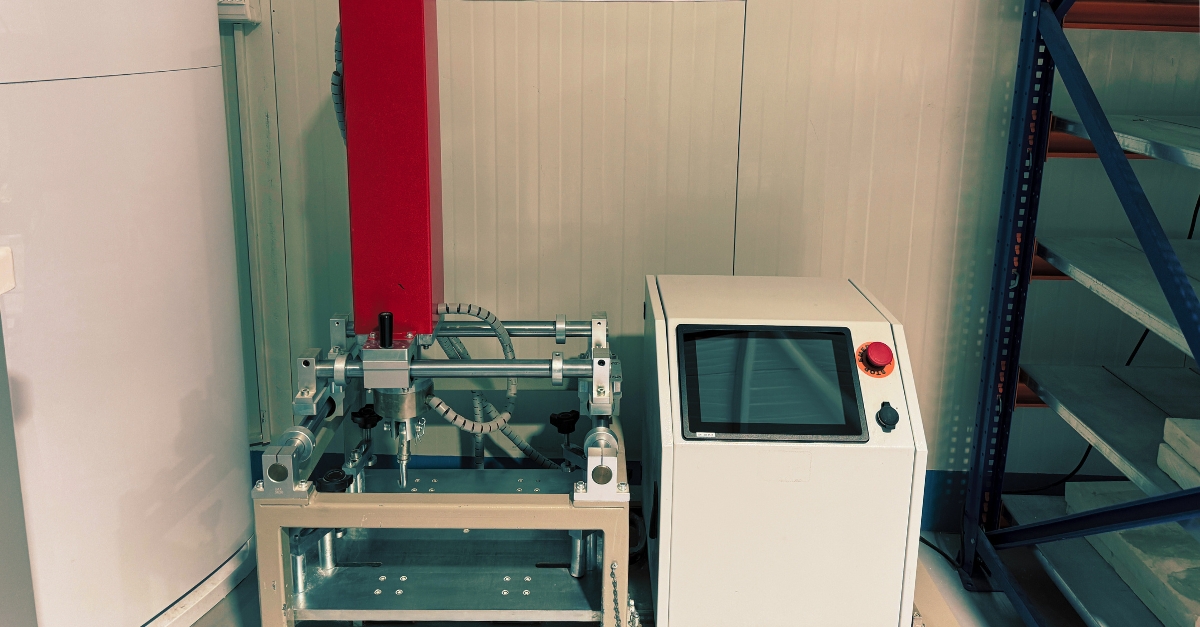

- Tensile Adhesion Strength Machine: This machine assesses the adhesive cement's resistance to failure under tensile stress. By applying tension to samples, the machine provides insights into the material's strength and durability.

- Mixer: The mixer is crucial for preparing adhesive cement mortar, ensuring consistency and uniformity in the material's composition. Components of adhesive cement are thoroughly mixed to produce a homogeneous blend that accurately represents the adhesive’s properties.